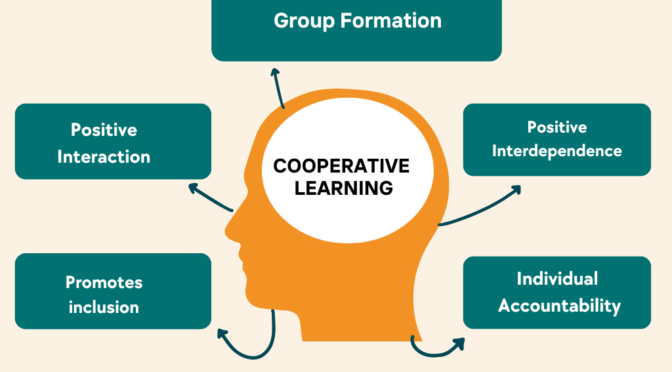

Cooperative learning is an instructional approach that emphasizes student collaboration, teamwork, and active participation in the learning process. It involves organizing students into small groups to work together towards a common goal or complete a task.

Here are the key elements and benefits of cooperative learning:

- Group Formation: Students are grouped heterogeneously, meaning they are intentionally mixed based on their abilities, backgrounds, and skills. This diverse grouping promotes collaboration and allows students to learn from each other’s strengths and experiences.

- Positive Interdependence: Each group member has a specific role or task that contributes to the overall success of the group. Students understand that their individual performance directly impacts the success of the entire group, fostering a sense of accountability and shared responsibility.

- Face-to-Face Interaction: Cooperative learning encourages students to interact and communicate with one another. They engage in discussions, ask questions, share ideas, and provide feedback to their peers. This interaction promotes active engagement and deeper understanding of the content being studied.

- Individual Accountability: Although students work in groups, they are individually accountable for their learning and contributions. Each student is responsible for mastering the content and completing their assigned tasks. This accountability helps prevent free-riding and encourages all students to actively participate and contribute to the group’s success.

- Cooperative Skills Development: Cooperative learning provides opportunities for students to develop essential social and interpersonal skills. They learn to communicate effectively, listen attentively, resolve conflicts, and cooperate with others. These skills are transferable to various real-life situations and contribute to the overall social development of students.

- Positive Interactions: Cooperative learning fosters a positive and supportive learning environment. Students learn to respect and value each other’s opinions, ideas, and contributions. This positive interaction enhances motivation, self-esteem, and a sense of belonging among students.

- Academic Benefits: Cooperative learning has been found to improve academic achievement. Through discussions, explanations, and peer tutoring, students can deepen their understanding of concepts and develop critical thinking skills. Working collaboratively also exposes students to different perspectives and encourages them to consider alternative solutions, leading to enhanced problem-solving abilities.

- Promotes Inclusion: Cooperative learning promotes inclusion by providing opportunities for students with diverse abilities and backgrounds to work together. It values the contributions of every student and creates a supportive environment where students with disabilities or learning differences can actively participate and learn from their peers.

- Enhanced Motivation: Working in groups can increase student motivation and engagement. Cooperative learning allows students to take ownership of their learning, share responsibility, and benefit from the collective achievements of the group. This sense of belonging and shared success can inspire students to become more invested in their learning process.

Cooperative learning can be implemented across various subjects and grade levels. Teachers play a crucial role in structuring group tasks, providing clear instructions, facilitating discussions, and monitoring group dynamics. It is important to establish a positive classroom climate, teach students how to work collaboratively, and provide opportunities for reflection and feedback to ensure the success of cooperative learning in inclusive education.

Also Read : Buddy System

Also Visit : Prep with Harshita

Holgura mecanica

Aparatos de ajuste: importante para el operación fluido y eficiente de las dispositivos.

En el campo de la ciencia contemporánea, donde la productividad y la fiabilidad del equipo son de alta trascendencia, los dispositivos de ajuste tienen un rol crucial. Estos equipos adaptados están concebidos para ajustar y estabilizar componentes giratorias, ya sea en herramientas de fábrica, medios de transporte de transporte o incluso en aparatos domésticos.

Para los técnicos en mantenimiento de dispositivos y los técnicos, trabajar con dispositivos de calibración es crucial para asegurar el rendimiento estable y confiable de cualquier mecanismo rotativo. Gracias a estas soluciones innovadoras avanzadas, es posible limitar notablemente las movimientos, el ruido y la tensión sobre los cojinetes, prolongando la longevidad de piezas importantes.

Asimismo relevante es el papel que tienen los sistemas de balanceo en la atención al usuario. El soporte técnico y el mantenimiento permanente utilizando estos equipos posibilitan ofrecer servicios de excelente estándar, mejorando la contento de los consumidores.

Para los dueños de emprendimientos, la financiamiento en equipos de ajuste y sensores puede ser esencial para aumentar la eficiencia y productividad de sus equipos. Esto es particularmente trascendental para los dueños de negocios que dirigen reducidas y medianas empresas, donde cada punto vale.

Asimismo, los aparatos de ajuste tienen una gran implementación en el área de la prevención y el monitoreo de nivel. Posibilitan detectar posibles defectos, impidiendo mantenimientos elevadas y perjuicios a los equipos. También, los indicadores obtenidos de estos sistemas pueden utilizarse para maximizar métodos y potenciar la reconocimiento en buscadores de búsqueda.

Las áreas de utilización de los equipos de equilibrado incluyen diversas sectores, desde la fabricación de transporte personal hasta el monitoreo de la naturaleza. No importa si se habla de grandes producciones industriales o modestos establecimientos hogareños, los dispositivos de ajuste son esenciales para asegurar un desempeño efectivo y sin presencia de detenciones.

gq3nfw

[b]Prevent Vibration Damage – Get Professional Balancing with Balanset-1A[/b]

Unbalanced rotors can cause serious damage to your machinery. Bearings wear out faster, motors consume more power, and failures lead to expensive repairs. [b]Balanset-1A[/b] provides professional-grade vibration diagnostics and balancing, helping businesses save money and improve reliability.

[b]Key Benefits:[/b]

– [b]Accurate & fast diagnostics[/b] – Identifies imbalance before it causes damage

– [b]Portable & efficient[/b] – Suitable for field and workshop use

– [b]User-friendly software[/b] – No special training required

[b]Choose Your Kit:[/b]

[url=https://www.amazon.es/dp/B0DCT5CCKT]Full Kit on Amazon[/url] – Includes all necessary sensors, software, and a protective case

Price: [b]€2250[/b]

[url=https://www.amazon.es/dp/B0DCT5CCKT][img]https://i.postimg.cc/SXSZy3PV/4.jpg[/img][/url]

[url=https://www.amazon.es/dp/B0DCT4P7JR]OEM Kit on Amazon[/url] – More affordable, comes with basic components

Price: [b]€1978[/b]

[url=https://www.amazon.es/dp/B0DCT4P7JR][img]https://i.postimg.cc/cvM9G0Fr/2.jpg[/img][/url]

Protect your equipment today with [b]Balanset-1A[/b]!

Balanset-1A: Advanced Mobile Balancer & Vibration Analyzer

Modern Dynamic Balancing Solution

Balanset-1A represents an revolutionary solution for dynamic balancing of rotors in their own bearings, manufactured by Estonian company Vibromera OU. The device ensures professional equipment balancing at €1,751, which is substantially less expensive than traditional vibration analyzers while preserving superior measurement accuracy. The system permits field balancing directly at the equipment’s installation site without necessitating dismantling, which is essential for minimizing production downtime.

About the Manufacturer

Vibromera OU is an Estonian company specializing in the development and production of equipment for technical diagnostics of industrial equipment. The company is incorporated in Estonia (registration number 14317077) and has offices in Portugal.

Contact Information:

Official website: https://vibromera.eu/shop/2/

Technical Specifications

Detection Parameters

Balanset-1A delivers accurate measurements using a two-channel vibration analysis system. The device measures RMS vibration velocity in the range of 0-80 mm/s with an accuracy of ±(0.1 + 0.1?Vi) mm/s. The operating frequency range is 5-550 Hz with optional extension to 1000 Hz. The system supports RPM measurement from 250 to 90,000 RPM with phase angle determination accuracy of ±1 degree.

Operating Principle

The device uses phase-sensitive vibration measurement technology with MEMS accelerometers ADXL335 and laser tachometry. Two uniaxial accelerometers measure mechanical vibrations proportional to acceleration, while a laser tachometer generates pulse signals for determining rotational speed and phase angle. Digital signal processing includes FFT analysis for frequency analysis and proprietary algorithms for automatic computation of corrective masses.

Full Kit Components

The standard Balanset-1A delivery includes:

Measurement unit with USB interface – main module with embedded preamplifiers, integrators, and ADC

2 vibration sensors (accelerometers) with 4m cables (alternatively 10m)

Optical sensor (laser tachometer) with 50-500mm measuring distance

Magnetic stand for sensor mounting

Electronic scales for precise measurement of corrective masses

Software for Windows 7-11 (32/64-bit)

Plastic transport case

Complete set of cables and documentation

Operating Capabilities

Vibrometer Mode

Balanset-1A operates as a complete vibration analyzer with abilities for measuring overall vibration level, FFT spectrum analysis up to 1000 Hz, measuring amplitude and phase of the fundamental frequency (1x), and continuous data recording. The system offers display of time signals and spectral analysis for equipment condition diagnostics.

Balancing Mode

The device supports one-plane (static) and two-plane (dynamic) balancing with automatic calculation of correction masses and their installation angles. The unique influence coefficient saving function allows significant acceleration of repeat balancing of identical equipment. A specialized grinding wheel balancing mode uses the three-correction-weight method.

Software

The user-friendly program interface offers step-by-step guidance through the balancing process, making the device usable to personnel without special training. Key functions include:

Automatic tolerance calculation per ISO 1940

Polar diagrams for imbalance visualization

Result archiving with report generation capability

Metric and imperial system support

Multilingual interface (English, German, French, Polish, Russian)

Fields of Use and Equipment Types

Industrial Equipment

Balanset-1A is effectively employed for balancing fans (centrifugal, axial), pumps (hydraulic, centrifugal), turbines (steam, gas), centrifuges, compressors, and electric motors. In manufacturing facilities, the device is used for balancing grinding wheels, machine spindles, and drive shafts.

Agricultural Machinery

The device provides particular value for agriculture, where reliable operation during season is critically important. Balanset-1A is applied for balancing combine threshing drums, shredders, mulchers, mowers, and augers. The possibility to balance on-site without equipment disassembly allows eliminating costly downtime during peak harvest periods.

Specialized Equipment

The device is effectively used for balancing crushers of various types, turbochargers, drone propellers, and other high-speed equipment. The RPM frequency range from 250 to 90,000 RPM covers practically all types of industrial equipment.

Superiority Over Similar Products

Economic Efficiency

At a price of €1,751, Balanset-1A delivers the functionality of devices costing €10,000-25,000. The investment recovers costs after preventing just 2-3 bearing failures. Cost reduction on outsourced balancing specialist services amounts to thousands of euros annually.

Ease of Use

Unlike sophisticated vibration analyzers requiring months of training, mastering Balanset-1A takes 3-4 hours. The step-by-step guide in the software allows professional balancing by personnel without specialized vibration diagnostics training.

Mobility and Autonomy

The complete kit weighs only 4 kg, with power supplied through the laptop’s USB port. This allows balancing in outdoor conditions, at distant sites, and in hard-to-reach locations without external power supply.

Universal Application

One device is appropriate for balancing the broadest spectrum of equipment – from small electric motors to large industrial fans and turbines. Support for single and dual-plane balancing covers all typical tasks.

Real Application Results

Drone Propeller Balancing

A user achieved vibration reduction from 0.74 mm/s to 0.014 mm/s – a 50-fold improvement. This demonstrates the remarkable accuracy of the device even on small rotors.

Shopping Center Ventilation Systems

Engineers effectively balanced radial fans, achieving lower energy consumption, abolished excessive noise, and extended equipment lifespan. Energy savings paid for the device cost within several months.

Agricultural Equipment

Farmers note that Balanset-1A has become an vital tool preventing costly breakdowns during peak season. Reduced vibration of threshing drums led to lower fuel consumption and bearing wear.

Investment and Delivery Terms

Current Prices

Complete Balanset-1A Kit: €1,751

OEM Kit (without case, stand, and scales): €1,561

Special Offer: €50 discount for newsletter subscribers

Bulk Discounts: up to 15% for orders of 4+ units

Ordering Options

Official Website: vibromera.eu (recommended)

eBay: trusted sellers with 100% rating

Industrial Distributors: through B2B channels

Payment and Shipping Terms

Payment Methods: PayPal, credit cards, bank transfer

Shipping: 10-20 business days by international mail

Shipping Cost: from $10 (economy) to $95 (express)

Warranty: factory warranty

Technical Support: included in price

Final Assessment

Balanset-1A represents an perfect solution for organizations striving to establish an successful equipment balancing system without substantial capital expenditure. The device democratizes access to professional balancing, enabling small enterprises and service centers to provide services at the level of large industrial companies.

The mix of affordable price, ease of use, and professional capabilities makes Balanset-1A an vital tool for modern technical maintenance. Investment in this device is an investment in equipment stability, decreased operating costs, and enhanced competitiveness of your company.